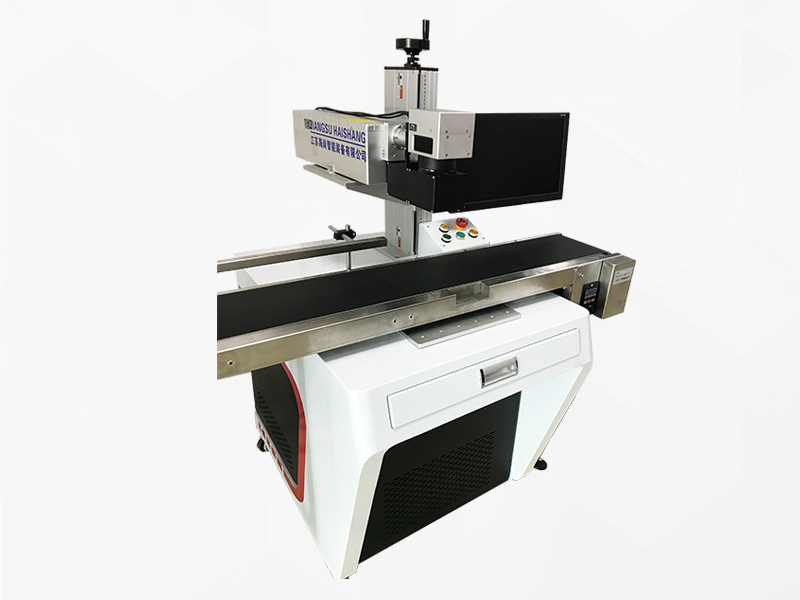

The laser coding system is composed of galvanometer scanning and the movement of the worktable on the assembly line; during the coding and marking process, the products flow continuously on the production line, which greatly improves the production efficiency and makes The laser machine meets the requirements of modern industrial production. Compared with the traditional marking machine, the marking content should not be too complicated, otherwise the marking speed will be affected. It will directly coordinate with the assembly line to reduce the loading and unloading manpower, and the operator can avoid the harsh production surroundings. Automated production greatly improves efficiency. The marking speed is fast and the output is increased.

1. No consumables, non-toxic, non-polluting, no frequent maintenance and cleaning, low operating cost;

2. Permanent mark, never wear, strong anti-counterfeiting function;

3. Support automatic coding, number skipping, and automatic generation of time and date.

Mainly used in online laser marking systems for wires and cables, pipes, electronic components, and hardware parts.

型号 | FB-20W/FB-30W |

平均输出功率 | 20W或30W |

激光波长 | 1.06µm |

激光频率 | 20-80khz |

标准雕刻范围 | 100mm*100mm |

雕刻深度 | <=0.3mm |

最小线宽 | 0.01mm |

最小字符 | 0.2mm |

喷码速度 | <=60字符/S |

流水线速度 | <=120m/min |

电力需求 | 220V 50Hz/60Hz |

整机耗电功率 | 500W

|